Elektro-Anlagen Röring GmbH equips biogas plants with Yaskawa AC drives

- Industrias

- Agricultura

- Energías renovables

- Aplicaciones

- Pumps & Compressors

- Cliente

- Elektro-Anlagen Röring GmbH

- EnviTec Biogas AG

- Productos

- CIMR-AC - Serie A1000

Delivery performance saves major contract

A major order was received from the US, but unexpectedly the AC drives ordered were not available. Like many companies, Elektro-Anlagen Röring GmbH was faced with a difficult situation in 2022. Nevertheless, a solution was quickly found: Yaskawa had the right components in stock - and impressed the company from Vreden (Germany) as the project progressed, not only with its high delivery performance, but also with the advantages of the universally applicable A1000 series of AC drives.

The "Green transformation" is still underway in the US. In this context, an energy source that has hardly been used in the US to date is gaining in importance, driven by the US government: biogas (renewable natural gas, RNG) from cattle manure. For the operators of large dairy cow farms across the country, the production of biogas and its processing into biomethane offers additional benefits. The biomethane produced locally and fed into the grid provides an additional source of income for the farms. And they therefore also make an important contribution to achieving climate and sustainability goals as well as to the decarbonization and energy security of the country. Biomethane production is also more sustainable than the currently prevalent energy production through fracking.

In many cases, the necessary production and processing plants are sourced from Germany, where biogas is already being produced on a larger scale than in the USA. EnviTec Biogas AG, an experienced player in the biogas plant market, relies on switchgear from the town of Vreden (Germany): Elektro-Anlagen Röring GmbH has been synonymous with customized electrical engineering since 1990. When it comes to maximum process stability for machines and systems, customers around the world rely on the experience and expertise of Elektro-Anlagen Röring's team of around 70 people.

Control cabinet technology for EnviTec Biogas

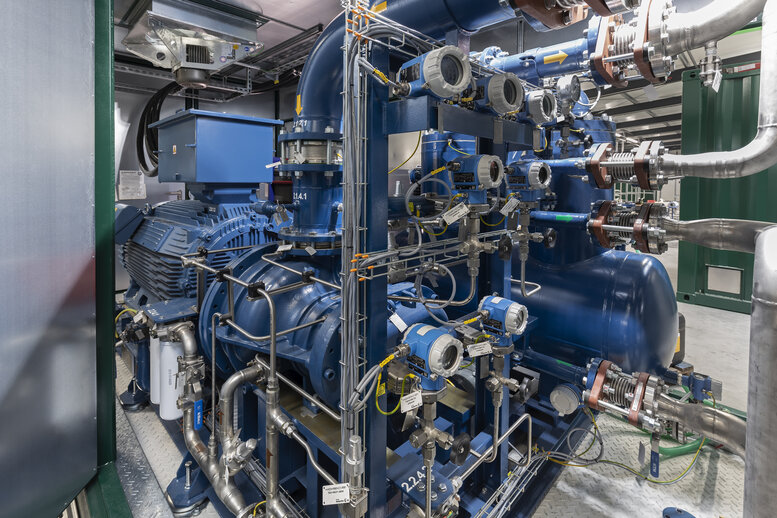

A current major contract includes the planning, programming and commissioning of the entire control cabinet technology for a total of eight new biogas production and processing plants for EnviTec Biogas AG, in which the biogas is enriched to a methane content of over 96 %, suitable for the respective gas grid. The required process pressure is generated with a frequency-controlled gas compressor"The economic operation of a biogas plant requires high capacity utilisation," explains Jürgen Tenbrink, Managing Director of Plant Engineering and Board Member of EnviTec Biogas AG. "This in turn is achieved through high technical availability, which we will ensure with our demanding quality standard."

Even for the electrical engineering professionals at Elektro-Anlagen Röring GmbH, a project of this scope was anything but ordinary. Flexibility and plant reliability are decisive factors, as the biogas plants must operate reliably as self-sufficient systems 'on greenfield sites' and often far away from technical supply centers.

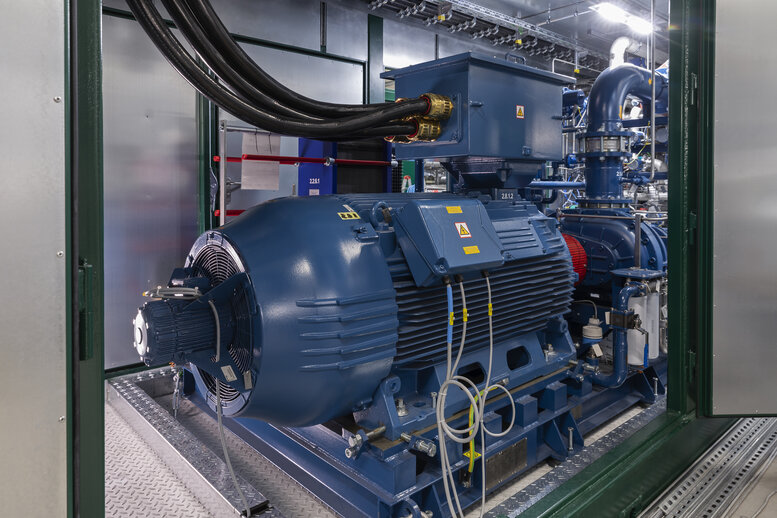

The situation became complicated when, at the end of 2022, the AC drives that had been ordered for the first installations could not be delivered due to the global chip crisis. These play a central role as drive controls for the biogas plant's compressor. And so plant director Sebastian Wolter and his colleagues got on their telephones. "We then found what we were looking for at Yaskawa, who were able to supply us with drives for 590 kW motors at short notice," he recalls.

The Japanese manufacturer, which has its European headquarters in Hattersheim (Germany), had four suitable models available at short notice - the result of a sophisticated supply chain that relies on Europe for the production of many components. "After intensive discussions with Yaskawa, we decided to purchase these drives before Christmas 2022. So we brought Yaskawa on board, and from then on we received excellent support," says Wolter.

This also meant that the newly developed multi-protocol communication cards for the required Profinet connection to the PLC were on their way in for initial storage. These were sent directly from the logistics centre in Idstein (Germany) to Vreden after being checked by Yaskawa's quality assurance department. A member of Yaskawa's technical sales support team then carried out the necessary updates to the drive firmware on site on the first day of cold commissioning. "It was a great collaboration!", says Sebastian Wolter.

A1000 drive series

Specifically, the devices supplied by Yaskawa are drives from its proven A1000 series. The series is ideal for biogas plants due to its good overload behaviour, compact size and low derating. The control methods available allow asynchronous and permanent magnet synchronous machines to be operated with or without encoder feedback. They are suitable for standard applications - such as energy-saving pumps, fans, extruders, mills and agitators - as well as for more complex drives with synchronous operation and positioning.

The intuitive and free DriveWizard parameterisation software ensures quick and easy commissioning, with auto-tuning and wizards to automatically adjust the relevant parameters to the connected motor and application. In the case of the 590 kW gas compressor, the integrated trend and oscilloscope functions helped to optimize the start-up. With the DriveWorksEZ software, individual switching and control tasks can also be easily integrated into the drive using block-oriented programming. The drive can replace a small PLC, reducing the cost, wiring and installation of the system. It also increases system reliability by reducing the number of components.

The A1000 complies with all international standards and has also been tested to US UL standard UL508C. The new multi-protocol communication card covers the world's most important fieldbuses, such as PROFINET, EtherCat, Modbus and EtherNet-IP, all in one. It is simply set to the required protocol via a DIP switch. Other option cards specifically for CANopen, DeviceNet, Profibus, CC-Link and MECHATROLINK-III are also available. This ensured compatibility with Elektro-Anlagen Röring GmbH's existing control environment from the outset.

Another advantage - especially for the planned use of the converters in biogas compressors in rural, remote areas - was the robust and low-maintenance design of the drives: Like all Yaskawa equipment, they are designed for ten years of continuous operation. Maintenance is therefore minimal. In addition, the drive uses built-in fault diagnostics to provide alerts on the status of key components, effectively preventing failure and costly system downtime. Should a service call be necessary, Yaskawa also has its own service centers in the US.